Replacement and repair choices for damaged linear actuators need a detailed study of the fault level and repair cost. Proper judgment also depends on safety concerns and how long the unit can still work. A wrong decision causes early removal of parts that can still be fixed or unsafe use of weak equipment. Multiple evaluation criteria guide optimal replacement timing. Equipment managers evaluating must consider structural integrity, economic repair feasibility, safety compliance requirements, performance degradation impacts, and preventive replacement strategies, determining when complete unit replacement becomes more prudent than attempting repairs.

Structural damage indicators

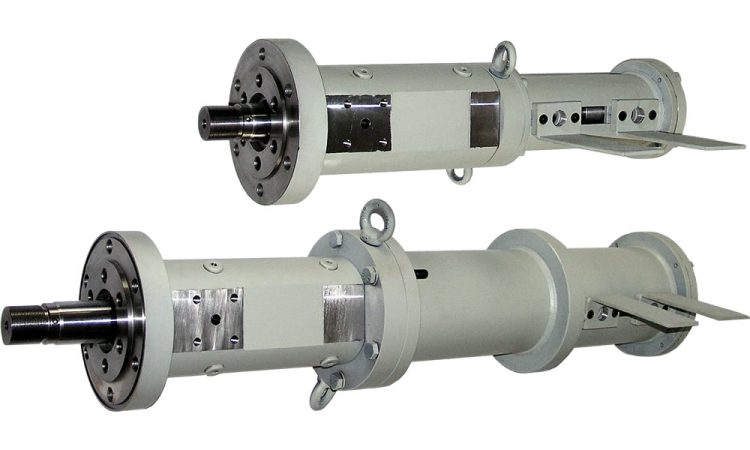

Cracking in barrels represents catastrophic failure, necessitating immediate replacement because welded repairs rarely restore original strength, and crack propagation continues under cyclic loads. Cylinder tubes with visible cracks indicate weakening over time due to stress points. These areas reveal that fatigue has gone beyond safe limits. Crack checks using magnetic particle or ultrasonic testing can find hidden fractures that cannot be seen by eye. Even small cracks reduce the strength to hold pressure. Explosions can occur when the cylinder is under full load. Continued use after cracks are found is not safe. Bent or twisted cylinder bodies appear due to impact, wrong side force, or faulty mounting. Such parts cannot be straightened again to the right shape or size. Creating lasting stress in the metal accelerates its failure in the future. The piston and seal of a Hydraulic cylinders with a bent barrel can stick. This leads to uneven wear and later complete loss of movement. Rod bending from column loading beyond design limits similarly creates alignment problems that no amount of seal replacement can resolve. The geometric distortion makes replacement the only viable solution.

Cost-benefit analysis considerations

A repair cost calculation must account for labour, parts, downtime, and failure risk probability, comparing positively with the cost of a new cylinder acquisition. Multiple seal replacements within short intervals indicate underlying problems where successive repairs attack symptoms rather than root causes.

- Cylinder boring and honing to remove scoring exceeds $500-2000, depending on size

- Rod rechroming costs $300-1500 per rod, depending on diameter and length

- Complete seal kits range from $50 for small cylinders to $500 for large units

- Labour charges of $75-150 per hour accumulate quickly during complex rebuilds

- Shipping costs for heavy cylinders add substantial expense to replacement options

Opportunity cost analysis considers production losses during extended repair periods versus quicker replacement installation. Emergency failures causing unscheduled downtime cost far more than planned replacement during scheduled maintenance. Frequent repairs consuming maintenance resources better deployed elsewhere tip calculations toward replacement. Volume discounts on bulk cylinder purchases or package deals with other components sometimes make replacement economically attractive even for marginally repairable units. Complete hydraulic cylinder replacement becomes necessary when encountering structural damage compromising integrity. Cost-benefit analysis favours new units over repairs, safety risks from continued operation, performance degradation beyond repair solutions, or preventive replacement timing based on service life. These criteria guide replacement versus repair decisions. Conservative replacement methods focus on safety and steady performance. These methods give better long-term value and reduce hidden costs. Aggressive repair methods wait until parts fail, leading to heavy loss from sudden stoppage and safety risk.